Wirbelstromprüfroboter ermittelt Restwandstärken von gusseisernen Kanälen. In Switzerland the INSPECTOR 5000 test robot with a SLOFEC inspection unit DN 350 was used.

Added together with the private sewer pipelines, the city of Zurich’s sewerage system measures a good 4000 kilometres. As a comparison, this is equivalent to the distance from Zurich to West Africa. The system is serviced and maintained by ERZ Entsorgung + Recycling. The elaborate sewer system removes the Swiss city’s entire waste water without polluting the ground water, streams, rivers or Lake Zurich.

The waste water from households and businesses is collected and taken to the treatment works. The system capacity is designed so that it can also take up rainwater and protect the built-up area from flooding.

Forming part of this sewer system are also various cast iron pipelines, some of which are almost 100 years old. In total they make up approximately seven kilometres and have a diameter range of largely 200 to 400 mm. These cast iron pipelines can only be inspected to a limited extent with established technologies, e.g. camera inspection, as these methods provide no information about the residual wall thickness and any corrosion. Ultrasonic inspection methods do not deliver the required results here either. The structure of the cast iron is not suitable for this type of examination.

In order to be able to determine the residual wall thickness of the cast iron sewers INSPECTOR SYSTEMS was commissioned by the city of Zurich to inspect the pipelines with the help of a special eddy current inspection system. For this the "SLOFEC" method of KONTROLLTECHNIK GmbH was used.

The SLOFEC method is based on the eddy current principle in combination with a magnetic field. From the inside of the pipe any possibly concealed corrosion on the outside of the pipe is detected. The detection capacity of this technology utilises its advantages in thick-walled, cast iron or even coated pipes.

During this pilot project, over only two "night shifts" in December 2011 approximately 200 metres of cast iron sewer pipelines with a nominal width of DN 350 under a busy street alongside Lake Zurich were inspected and the residual wall thickness fully documented. On the basis of the inspection results the city of Zurich will now decide which sections of the sewer actually have to be renovated.

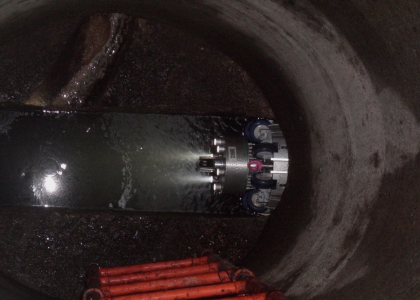

In Switzerland the INSPECTOR 5000 test robot with a SLOFEC inspection unit DN 350 was used. This robot travels through pipelines forwards and in reverse with the tried and tested drive technology by Inspector Systems, and during this inspection it does not come to a standstill when it encounters bends in the pipe. With the adapted SLOFEC eddy current testing unit before the drive unit the eddy current signals relating to the wall thickness were directly recorded during the run and transmitted to the evaluation computer. This processes the eddy current signals in graphic form so that the preliminary results were immediately available online at the time of the inspection run.

The complete robot is designed so that it can also traverse connection pipes to houses. Its water-tightness is a further feature of this model.

The inspections were carried out during rainy weather and with the sewage pipes in operation, whereby the city of Zurich carried out any necessary shut-off measures in the sewage system.

At the start of the inspection run the inspection robot was introduced into the pipeline though open manhole structures measuring approximately one metre in diameter and then taken out again at the same place.

Because of the flexible design of the inspection robot no modifications had to be made to the manhole structure, which was the basis of the entire project.