For the 28th fuel element replacement and for annual plant inspection the Grafenrheinfeld nuclear power station was disconnected from the network on 6th March 2010. During this inspection it was the task of INSPECTOR SYSTEMS to inspect sections of the TH pipeline system with the aid of remote-controlled pipe robots.

For this, INSPECTOR SYSTEMS together with two other companies led the development of a total of three special pipe robots with which a visual inspection, an eddy current inspection and an ultrasonic wall thickness measurement can be carried out. Also, if necessary, curved longitudinal seams and round seams can be ground. The special challenge relating to the design of the pipe robots was that they had to be introduced into the pipeline through a valve with a small diameter.

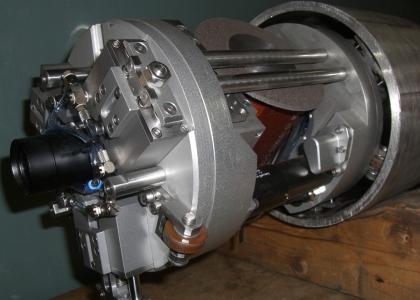

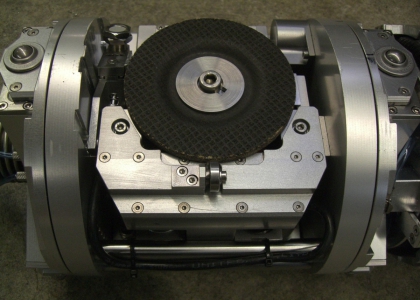

For carrying out work on the inner pipeline surface a grinding robot was designed. This is based on the grinding robot technology for the internal machining of welding seams in nuclear power stations developed by INSPECTOR SYSTEMS and qualified by various national and international companies. The grinding robot grinds curved longitudinal seams of the TH pipeline and is designed so that curved longitudinal seams, round seams and also the basic material of the pipeline can be ground. The grinding module comprises a powerful three-phase current motor with a grinding disk, a rotating unit with a rotating angle of 380° and a radial stroke for the grinding motor. For finding the curved longitudinal seams to be ground, the robot is fitted with an inductive sensor and an inclinometer.

A locking devices seals the section of the pipe system ahead of the grinding unit off against grinding dust and thus prevents grinding dust being carried along within the pipe system. In order to inspect pipe bends simultaneously with the eddy current and ultrasonic process, an eddy current-ultrasonic inspection robot was developed. It is fitted with two pivoting sensor arms and rotates continuously. A cardan suspension system allows the sensors to be guided orthogonally to the surface being inspected. The rotating unit with a slip ring ensures a continuous rotary motion of the sensor arms. The inspection module developed by the company Kontrolltechnik was adapted to the INSPECTOR SYSTEMS drive system. With this combination vertical pipeline systems of the TH system can also be checked.

An inspection-suction robot was also developed which combines two functions in one machine. It comprises a video inspection unit for qualified visual inspection within the TH pipeline system and a suction unit for cleaning the pipeline after grinding. The inspectionsuction robot includes a highresolution camera module with 10 x optical zoom, automatic and manual focussing and a powerful lighting element, the lighting intensity of which is controllable. The inspection unit is also fitted with a laser which is integrated into the rotating unit and can therefore reach every point on the inner circumference of the pipe. It allows pipeline sections to be measured to an accuracy of 0.2 mm. In this way the laser is used for the precise evaluation and classification of the camera image.

The suction unit is mounted on the rotating unit of the pipe robot. It comprises a suction tube, a guide pipe, a camera and a motor tube stroke. The suction tube is moved in the direction of the pipe wall via a stroke and the suction process is monitored with the suction camera. With the inspection / suction robot it is therefore possible to reach every point of the TH pipeline and to carry out targeted suction there.

All three robots are based on the tested and qualified INSPECTOR SYSTEMS concept. They each comprise three drive units and an inspection and machining head. The modules are flexibly connected to each other by means of folding bellows. This allows the entire TH pipeline system, including vertical sections and bends with a bending radius of 1.5 D to be traversed. The pipe robots were qualified with no objections together with the operator E.ON nuclear power and the assessor TÜV Süd and were successfully deployed during the inspection at the Grafenrheinfeld nuclear power station.