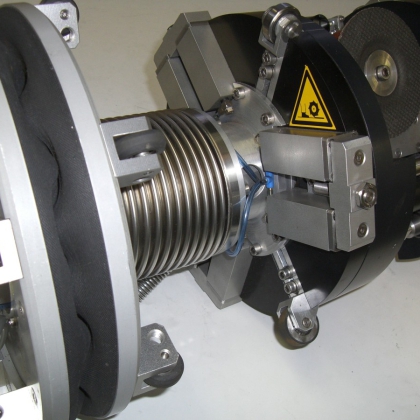

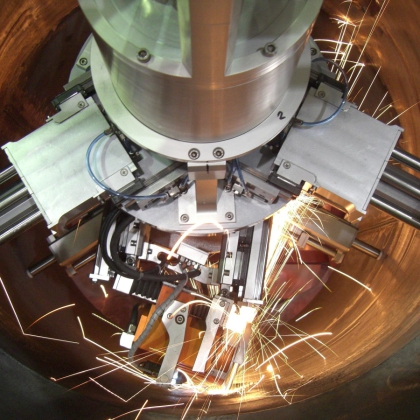

Robots with grinding capabilities have been especially developed by INSPECTOR SYSTEMS for the removal of weld roots within the interior of pipe systems.

Grinding welding seams down is important when it becomes necessary to make an inspection of the pipe line. Removal of the joins ensures quality and accurate test results.

One sided welding seams with in a section of pipe can be inspected with the help of ultrasound and eddy current techniques as well as with radiographic testing and dye penetration tests. These checks should be regularly repeated during routine maintenance and system shut downs. The results can be greatly affected by the presence of weld roots on the inner wall of the pipe. Weld roots on the inner side of a welding seam can greatly distort inspection results because it becomes difficult to establish whether what is being examined is either a small tear or in fact welding roots.

By using a Grinding Robot, weld roots can be easily removed so that accurate and reliable test results can be obtained. More over, removing the weld roots leads to an improvement of the interior of the pipe wall. This means that the resistance of the welding joins in relation to both mechanical and thermal wear is increased.

The robots can be easily deployed through gate valves in the pipe line and controlled remotely in order to locate whatever join the operator may require.

As an extra to the standard Grinding Robot it is also possible to furbish customers with robots that meet their specific and individual requirements.

The robot technology and the qualified grinding respectively polishing process are approved by different national / international companies and risk management organisations.

TIPP: Grinding Robots from INSPECTOR SYSTEMS in offshore applications