Inspector Systems

Our strengths are many years of acquired know-how,

and reliable service.

and reliable service.

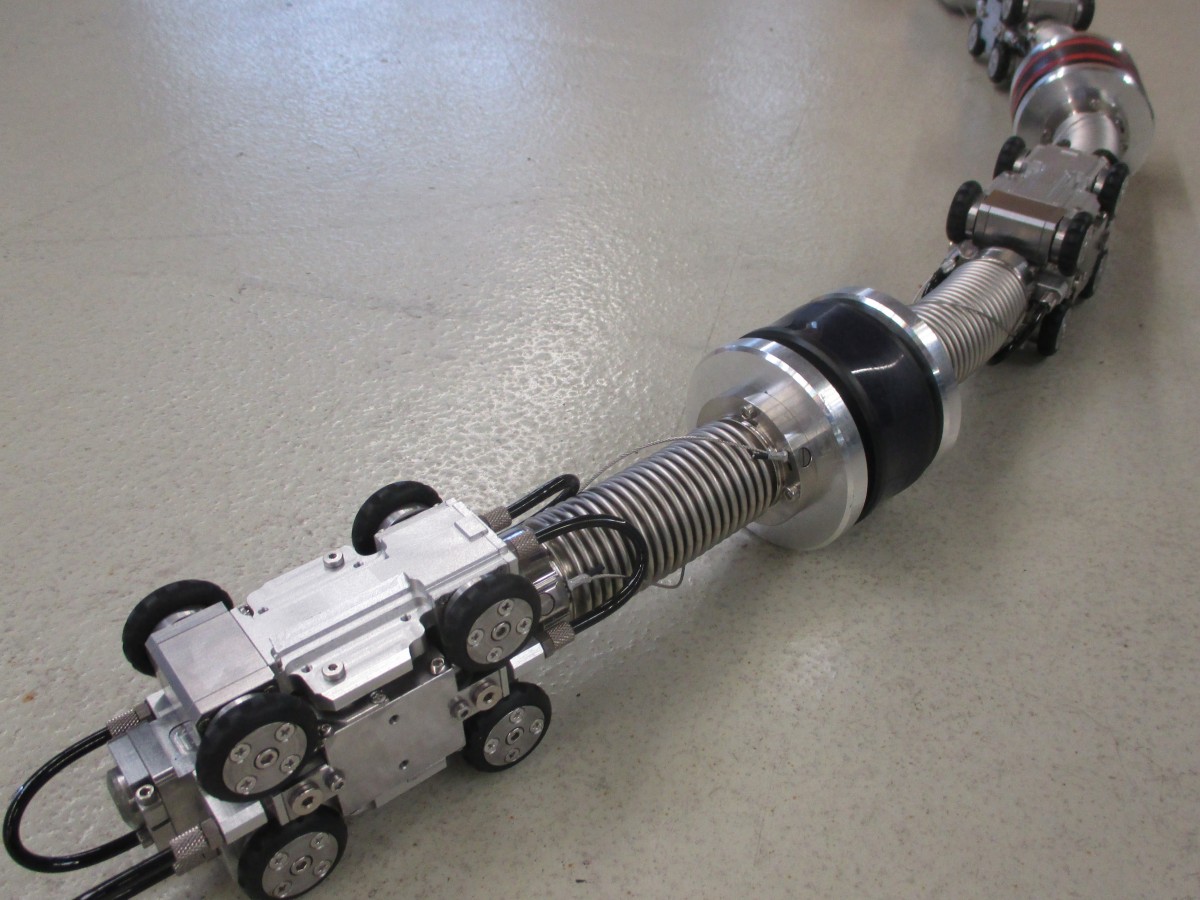

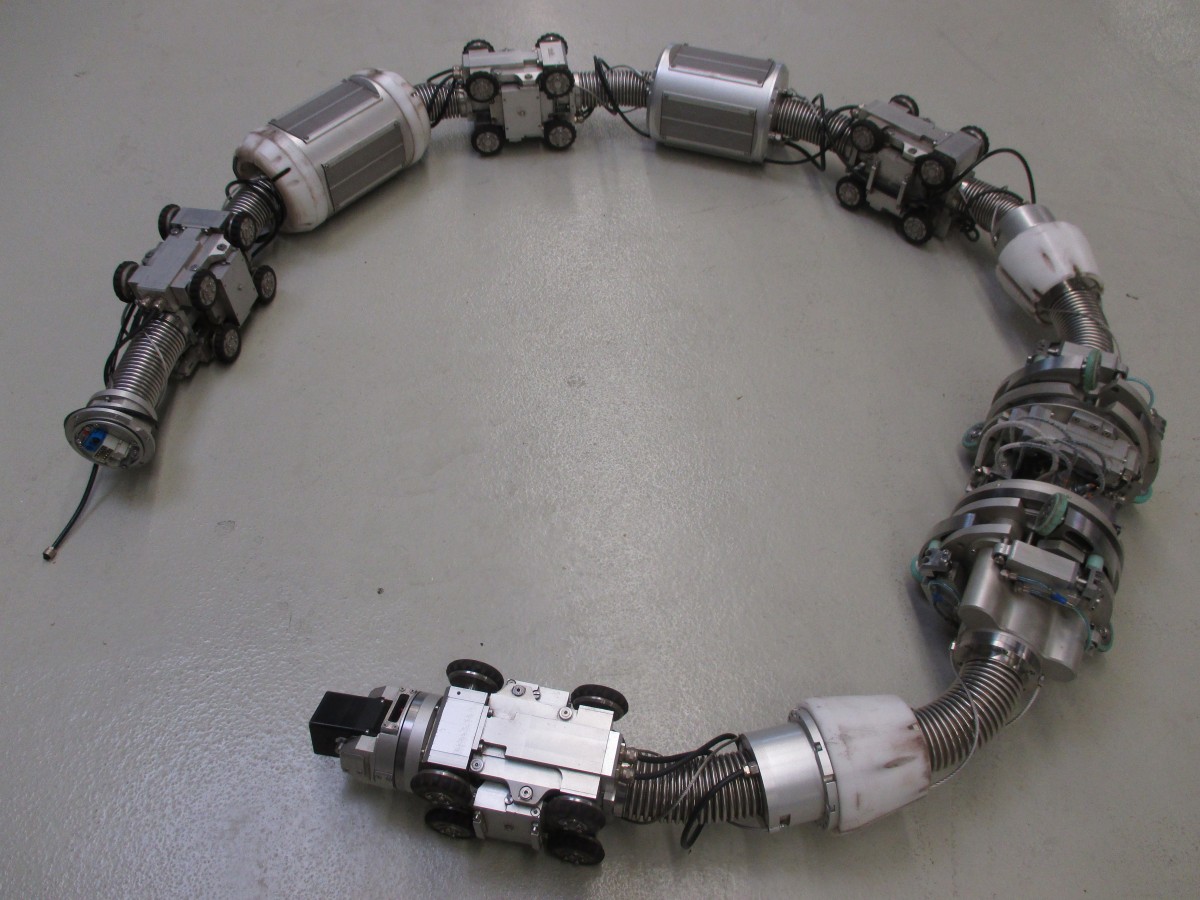

Pipe crawler

Designed for inspection, testing and machining

within complex pipelines.

within complex pipelines.

News

Worldwide interesting news and reports

from our daily work.

from our daily work.

Contact

Please contact us, we also find the right solution for

your problem.

your problem.

Directions

Visit our company and convince yourself of our practice-

oriented developments.

oriented developments.

Inspector Systems

Pipe crawler

News

Contact

Directions

Technical installations that are subject to stringent requirements should always be kept on the best possible level of operational safety. This applies particularly to installations with their innumerable piping systems that require a high degree of reliability, comfort and safeness. Keeping individual pipeline sections in perfect condition is a crucial prerequisite for the trouble-free operation of the entire system. The pipeline systems therefore have to undergo strict and regular tests of various types which ensures that any damage to the pipes as a result of wear, corrosion, erosion and cracking etc. is detected, respectively prevented at an early stage. Subsequently it can occur that a detected damage is not accessible from the outside and a repair by appropriate means must take place from the inside.

Inspector Systems is a specialist in manufacturing of self-propelled, tethered and remote controlled pipe robots for internal inspection, non-destructive testing and machining as well as to provide worldwide services, especially for so called „challenging pipelines“ or buried-, difficult to access- and complex pipe structures of any kind. Examples are pumping lines and tank to tank connections in refineries, street-, railway- or river crossings, pipes in nuclear-, thermal- and conventional power plants, feeding pipes in gas-, oil- and offshore constructions etc. The modular and flexible design of the pipe robots makes it possible to equip them with different inspection-, testing- or machining modules as well as to insert through limited accesses and to drive pipe systems bi-directionally through bends and inclinations.

News: Latest news about our activities around the world.

16 May 2025

World Nuclear Exhibition 2025 / 04. November - 06. November / Paris Nord Villepinte / Hall 6 - Stand N34

30 March 2024

INSPECTOR SYSTEMS offers the customer full-service support A nightmare for every customer. They order a product, it is delivered, something is wrong, there are still questions unanswered. And now he can no longer reach the contact person, ends up in a call center, has to initiate sluggish email correspondence. Not with us: We focus on comprehensive support and advice in every phase of the project! Our customers also receive full support after delivery.

30 November 2023

Growth from a one-man engineering office to a global player INSPECTOR SYSTEMS, a pioneer from the very beginning as a developer and manufacturer of pipe robots for the internal inspection, testing and processing of complex pipe structures, celebrated its 40th anniversary. Founded in November 1983 by Rainer Hitzel, the company, which is still owner-managed today, has developed into a global player with its innovative pipe robot technology. The pipe robots from Rödermark have been sold or used in service projects in a total of 31 different countries on five continents.

31 October 2023

Order for the development of a total of 13 non-destructive testing and processing robots Framatome offers comprehensive solutions for the development, construction and maintenance of nuclear power plants. Its services include a range of design and manufacture of components, the development and production of nuclear fuel and fuel elements as well as a broad portfolio of services for reactors. Framatome employs around 14,000 people and has been a subsidiary of the EDF Group since 2018.

Our best case studies…

-

Inherit particles / sections from any outlineYou can now inherit particles, attributes, and sections from one outline to another.+G5One Epic Framework19Modern Templates

-

A mobile responsive, mobile friendly experienceProtean adapts to the viewing device, whether a smartphone, tablet, or laptop.+G5One Epic Framework19Modern Templates

-

A most powerful and versatile Layout managerThe Layout Manager features an infinitely simple drag-and-drop interface.+G5One Epic Framework19Modern Templates

-

Particles make creating content quite simpleProtean comes with many powerful particles that you can use as building blocks.+G5One Epic Framework19Modern Templates

-

Style your content using a variety of settingsChoose from an array of preset style variations, each with extensive options.+G5One Epic Framework19Modern Templates

Gantry 5's administrative interface has been completely rebuilt from the ground up to meet the needs of tomorrow's developer, today. The admin provides multiple options for styles, layout, particles, and more.

Set up and configure page layouts with Gantry 5's new Layout Manager. Featuring drag-and-drop functionality that gives you the power to place content blocks, resize them, and configure their unique settings in seconds.

The template styling is built with SCSS, a programmable stylesheet language for CSS, making the CSS more dynamic and adaptable. You can easily enable and disable automatic recompilation of SCSS files.

Configuration in Gantry 5 features sophisticated built-in fields such as Icon Picker, Image Picker, Font Picker, Collections, and much more. You can change almost any aspect of a theme without breaking out a single editor.

Protean is built with a responsive layout, which means it automatically adapts to the viewing device, so it will expand and contract accordingly to the size and resolution of the screen, whether mobile, tablet or desktop

© 2006 - 2024 by Inspector Systems.