Atlanta Gas Light Company (AGL) with head offices in Atlanta (Georgia) is the largest natural gas supply company in the southeast of the USA. Via its extensive pipeline network it supplies a total of 4.5 million households with natural gas.

Every day Colonial Pipeline delivers approximately 30 million litres of diesel, petrol and other oil products throughout the southeast of the USA. The pipeline network for this is around 10,000 km in length. Both companies are therefore very important cornerstones in assuring that the USA is supplied with oil and gas.

To guarantee the pipeline infrastructure of the two companies the wall thickness of various pipeline sections at particularly critical points in the region of tank stores or also road or river passages was determined.

The underground pipelines with a diameter range of 24 to 30 inches were checked for any areas of corrosion using the SLOFEC testing procedure in collaboration with GE Inspection Services and Kontrolltechnik GmbH.

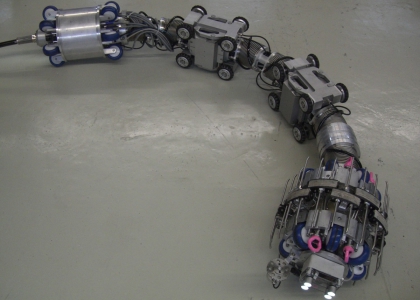

For this a SLOFEC inspection robot was deployed which examined emptied partial sections with 90 degree bends and pipeline sections inclined at 30 degrees over a length of up to 200 metres. The inspection robot was introduced into the pipeline through valves in sometimes very constricted spatial conditions and inspected each of the pipe sections in uncleaned condition. As an explosive atmosphere can prevail in gas and petroleum pipelines, the pipe sections were constantly flushed with nitrogen during the inspection and an oxygen sensor was fitted to the inspection robot itself.

It automatically switches the robot off if the oxygen content in the pipeline is too high in order to prevent any risk of explosion. In this way even these critical pipeline sections could be safely checked.