In 2004, the energy group EDF announced the construction of a third reactor in Flamanville, France, involving the third generation of pressurised water reactors, the European Pressurised Water Reactor (EPR), which the French company Atomholding AREVA and Siemens have been producing since 1992.

Three years ago INSPECTOR SYSTEMS was awarded the contract to develop grinding robots for grinding internally located welding seam. These grinding robots cover pipe diameters of DN 100 to DN 500 and can traverse valves, bends and vertical pipe sections – all standard features of INSPECTOR SYSTEM robots. In addition to the grinding robots, exhaust units were developed for the pipe diameters in question. By way of suction, these units remove the dust produced by the grinding work and ensure that the pipe is left in a clean condition.

Once again, during the past year even higher requirements relating to the quality of the ground welding seams were set. Accordingly, the angle of the ground welding seam resulting from the linear misalignment of the two pipes must not exceed 7°.

As there were no measuring systems available that were suitable for these requirements, during last year INSPECTOR SYSTEMS obtained the contract to develop and construct laser scanning robots especially for this application.

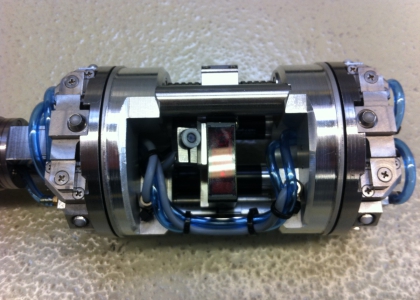

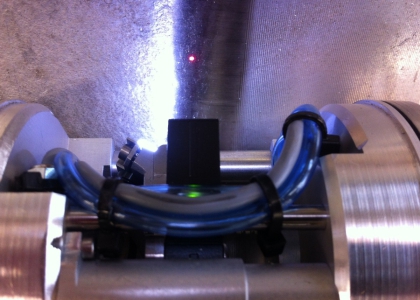

Just like the grinding robots, the laser scanning robots must cover the diameter range from DN 100 to DN500 and must be able to travel through valves, bends as well as vertical pipe sections. After intensive discussions with the customer, Areva, INSPECTOR SYSTEMS decided to use a point laser for measuring the ground welding seam. By way of a highly-precise centring unit, this point laser is centred in the milled region of the welding seam and travels over the welding seam with the aid of an axial motor unit.

At the same time a laser profile is recorded in the software specially developed for these measurements. In order to take measurements at several points of the welding seam, a rotary unit is integrated between the two centring units, allowing the laser measuring point to be positioned at the required location in the pipe. Four axial scans are envisaged for measuring one welding seam, the first axial scan is carried out at 0°, the second at 90°, the third at 180° and the fourth at 270°, so that the welding seam can be scanned all the way round.

Once the individual axial scans have been taken, the laser profiles, which at all times are continuously recorded with the help of the software, can be called up and the angle of the ground welding seam can be shown directly in the laser profile by two cursors. The software calculates this value automatically and displays it directly in the laser profile scan. Additionally, it is also possible to carry out several measurements in one laser profile and have these displayed. This graph, containing the measurements, can be printed out directly or saved as a data set.

Apart from the design aspects, the development of the laser software was a great challenge which could be very well met through the comfortable and intuitive operability of this software.

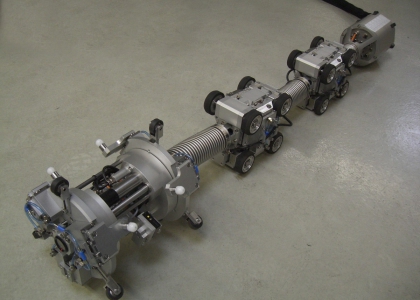

Three laser scanning robots were developed so that the diameter range from DN 100 to DN 500 could be covered. The smallest of the three is designed for diameter DN 100, and in spite of its very small size it is technologically on a par with its bigger brothers. The middle of the three laser scanning robots has to cover the greatest diameter range, which extends from DN 250 to DN 350.

The design difficulty faced in this case was to come up with a laser scanning robot that is small enough for the measuring system to function at DN 250, but at the same time large enough so that the measurements can be carried out at DN 350 without a loss of quality. The biggest of the laser scanning robots is designed for the DN 500 diameter range and also meets all the requirements placed on it.

At the end of last year, during comprehensive acceptance tests all the robots were put through their paces by AREVA NP, EDF and Bureau Veritas, were qualified and are now available for deployment in France.