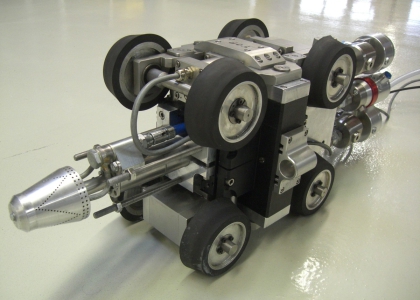

On the one hand the newly developed coating robot is based on Inspector Systems’ pipe robot technology, and on the other hand on the Humidur® epoxy coating produced by the Belgian company Acotec.

Internally coated pipes are required everywhere where aggressive or abrasive media can attack the pipe when in operation. Using the coating robot, a 1 mm coating can be applied evenly and in a controlled manner to pipe sections measuring up to 100 m, without them have to be excavated or dismantled. The coating of welding joints after the laying of internally coated pipes is also possible. At present the diameter range of the first prototype is approximately 300 to 500 mm.

The coating robot is designed in such a way that a special coating unit with a rotating spray nozzle is adapted on a drive system with a camera. By way of the drive system the coating unit can be moved through the pipe section. Then, while travelling steadily in reverse, the epoxy coating is sprayed on to the inner wall of the pipe.

Because of the flexibility of the coating robot it can traverse tight bends and vertical pipe sections. In this way the internal coating of complex pipeline systems is also made possible.

The epoxy coating with the brand name Humidor® comprises a solvent-free dual-component mixture which is supplied from outside via a tempered hose.