50m vertical pipelines in the Penly nuclear power plant in France are no problem for pipe robots from INSPECTOR SYSTEMS

In September 2014 various vertical pipelines were inspected in the Penly nuclear power plant in France by INSPECTOR SYSTEMS. The Penly nuclear power plant is situated in the Upper Normandy region on the English Channel. It consists of two pressurized water reactors, each with a net output of 1330 megawatts.

Every year it feeds on average 18 billion kilowatt hours into the public power grid, this represents about 80 percent of the annual power consumption of Normandy. Construction of the reactors began in 1982 and they were completed in 1992. EDF operates the nuclear power plant.

The Électricité de France SA (EDF) is a state dominated French electricity company listed on the stock exchange. EDF is the second largest electricity generator worldwide and presently employs over 158,000 employees for the supply of about 37 million customers.

Each reactor has two so-called spray pipes, which lead onto a ring with spray nozzles in the dome of the reactor building.

These pipes are emergency lines in the control area for cooling the reactor and have an inside diameter of approx. 346 mm. The biggest challenge with these lines was that they were approx. 60 m long, 50 m of which ran vertically upwards. In addition seven 1.5xD 90° bends had to be passed through in both pipeline sections.

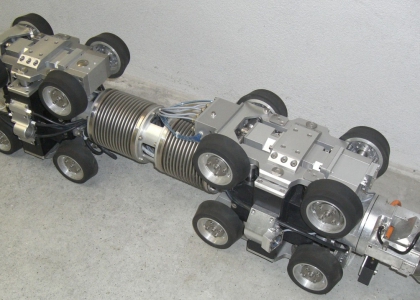

Through a removed valve the pipelines were travelled through from below, starting with the Type 5000 Video/Laser inspection robot. The decision to award the job to INSPECTOR SYSTEMS proved to be a very good one, as demonstrated during both inspection runs, as for the first time the lines could be travelled through and inspected completely forwards and backwards.

After about 60 meters the pipeline narrowed from 346 mm to 211 mm, so that the limits for the video/laser inspection robot were also reached here. Nevertheless, thanks to the camera technology with a 10x optical zoom a further 10 meters could be inspected in the narrowed pipeline and 10 meters into a branch, which was also situated at the end of the line.

As a result of the two inspection runs it was possible to confirm the perfect condition of the visually inspected areas. This was also described to the customer in two inspection reports. Due to the professional work of INSPECTOR SYSTEMS the operator EDF decided to have further similar inspections carried out in various other nuclear power plants.