Whether it's district-heating lines, loop reactors for manufacturing polymers, or... there are manifold application areas for ultrasound test robots from Inspector Systems.

The industrial use of ultrasound tests in the steel industry began over 50 years ago. At that time the emphasis was foremost on fault testing. The application spectrum was later expanded to include wall-thickness testing. Today wall-thickness measurement is one of the most frequently occurring ultrasound applications in the world of non-destructive materials testing. Especially in the pipe industry, considerable efforts to use ultrasonic wall-thickness measuring systems were also undertaken in years past — for good reason!

The client frequently wants to know how erosion and corrosion damage or other material losses occurring from use of the pipeline have affected wall thicknesses in the pipeline network. But how do you test from outside difficult-to-access pipelines that have been laid underground or above ground in dense pipe networks? And what is necessary if a pipeline-opening access to the pipe system indeed exists, but the subsequent pipeline route leads through several bends and vertical sections? Practically no provider on the market can traverse such complex pipe structures from inside and professionally conduct a test. Costly earthworks, street closures in thickly settled areas, or elaborate scaffolding installations are the result.

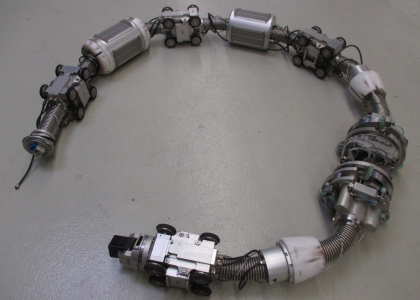

INSPECTOR SYSTEMS has long been the expert company for developing and constructing highly developed ultrasound pipe robots for internal pipe-wall testing. In-house specialists, who can operate the pipe-robot technology on the one hand and on the other don't just apply the ultrasound test technology but can also analyse it, provide the client with testing applications from a single source.

A special application of the ultrasound test technology from INSPECTOR SYSTEMS is being increasingly requested in this connection: the internal inspection of district-heating networks. For instance French energy supplier 'Compagnie Parisienne de Chauffage Urbain', CPCU for short, which distributes heat for heating via a pipeline network nearly 500 kilometres long. This runs along many buildings in the city of Paris, which comprise around a third of the entire building stock. Among them is the Louvre Museum housing Leonardo da Vinci's world-famous oil painting, the Mona Lisa.

This pipeline network involves a steam network. The steam generated from various heat sources is distributed through the main pipeline network to steam-water heat exchangers at a temperature of 235 °C (455 °F) and a pressure of 20 bar (290 psi). The hot water flows from there into the buildings' heating systems and is subsequently returned through return lines. The return lines consisting of steel become clogged due to corrosion promoted by the condensate. Furthermore the support fasteners and pipeline guides welded on are critical points.

Such a steel condensate-return line with an inner diameter of 260 mm and a wall thickness of 6.5 mm had to be investigated at specified critical points for wall-thickness reduction from corrosion as well as from rust penetration. Testing was done along a length of 60 metres in the horizontal and vertical direction while travelling through five bends. It was the perfect task for INSPECTOR SYSTEMS's ultrasound test-robot technology. The pipe's interior surface was scanned at 100 per cent over the entire length of the pipe; flaws were displayed directly on the monitor. The overall result was documented in a comprehensive test report. Due to its extreme flexibility, little room was needed to get the robot into the pipe system, because in Paris larger street openings intended for getting test equipment in always mean increased organizational complexity with sustained traffic congestion. Not to be overlooked is the added expense of inspecting street sections that contain asbestos in parts.

Bremerhavener Entsorgungsgesellschaft, an energy producer on the North Sea in Germany's far north, operates an entirely different district-heating network. Connected to the local waste-to-energy plant is a district heating system, which feeds hot water at a temperature of 120 °C (248 °F) and 5 to 6 bar (72 to 87 psi) in a 15 kilometre long district-heating network. District-heating lines are clad with insulation to avoid heat losses. While at CPCU the lines are mainly routed in a concrete channel, in Bremerhaven they're laid directly in the soil. Thus especially in older line networks the risk increases of insulation becoming damaged after years of operation. Water gets between the insulation and the pipes' surface as a consequence. This results in the formation of corrosion. The undesired result is the diminution of wall thickness.

The measuring method of INSPECTOR SYSTEMS's ultrasound test robot works according to the general ultrasonic pulse-echo procedure. The transit time of the medium in the bodies to be tested is measured with this procedure. As with the echo sounder, short, ultrasonic pulses are generated with the aid of piezoelectric transducers in the ultrasonic probes and introduced into the material via the aqueous coupling medium. Coupling with water is necessary, because air exhibits too rapidly increasing attenuation with frequency. On the other hand ultrasound propagates with little attenuation in liquids. Ultrasound test heads, or their piezoelectric transducers, intercept echoes reflected from the pipe's outer wall. Determining and distinguishing flaws on the interior and exterior of the pipe's surface is thereby possible. The pipeline in Bremerhaven is to be tested for precisely these wall-thickness reductions due to corrosion on the pipe's exterior surface.

One of the pipelines first has to be inspected for text purposes and, if successful, additional line sections for the purpose of evaluating the ultrasound results. After the temperature inside of the pipe fell below 45 °C (113 °F) a couple of days later, the ultrasound test robot was deployed through a specially prepared insertion pipe and then successfully tested a spirally welded line with an inner diameter 235 mm and wall thickness of 5.2 mm along a length of 100 metres. Sequel follows...!

On the other hand determining the wall thicknesses of two of Brazilian plastic producer Braskem's loop reactors at its European production site in Schkopau, Germany required an inspection with a very special task. Here thousands of tonnes of polypropylene, a thermoplastic with a wide range of applications, are manufactured each year. Loop reactors, the columns of which have an inner diameter of 580 mm, a wall thickness of 15 mm and a height of over 40 metres, are used for circulation during the manufacturing process. And that was precisely the special challenge: perpendicularly 40 metres upward and back down. It wasn't a problem for the ultrasound robot, because the task was completed with flying colours just as it was in 2009 with the previous owner, Dow Chemical.