Various radiographic tests were conducted on weld seams during the routine annual inspection at a German nuclear power station.

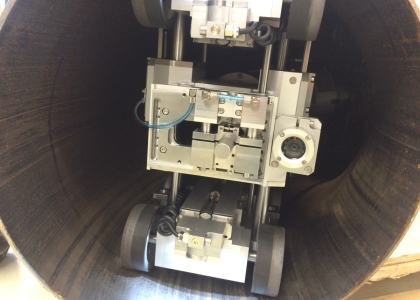

Time was a critical factor having a major influence on this project's success due to the short-term planning and narrow time window during the shutdown. INSPECTOR SYSTEMS was able to score points using a customer-specific design solution to reduce of the time cost by quickly rebuilding an existing pipe robot and making it usable for positioning an iridium source. Only that enabled testing of the weld seams in the interior area. The positive effect was a significant time savings in comparison to the conventional measuring method from outside.

The iridium source first had to be mounted on the robot after extensive tests outside of the control area. That succeeded despite the difficult conditions due to prescribed safety precautions within the control area.

Inserting the robot fitted with the iridium source into the emergency and residual heat removal system through an isolation valve proved possible after carefully preparing the line for the radiographic test. A challenging pipe run considerably impeded the task of exactly positioning the iridium source. The iridium source had to be placed at the centre directly in front of a recess inside the line at both bend-connection joints as well as at weld seams. But the robot's precise setting possibilities and the well-trained staff from INSPECTOR SYSTEMS were able to master even these challenges. Ultimately all of the required areas of the emergency and residual heat removal system were subjected to a radiographic test as planned. This way INSPECTOR SYSTEMS was able to deliver an important contribution that enabled the nuclear power station to be resynchronized with the power grid without further delay.

E.ON Kernkraftwerk GmbH thanked us after the successfully concluded project in a letter of reference worded as follows: 'Your staff came very positively to our attention due to their highly motivated, engaged, and confident way of working. […] We thank you and your whole team (including your shop personnel) for the effort set out above, which contributed to the nuclear power station's ability to be safely resynchronized with the power grid.'