Laser inspection robot used at EEW for calibration during pipe manufacture.

The EEW Group, or more specifically its member the Erndtebrücker Eisenwerk GmbH & Co. KG, specializes in the production of steel pipes. The company is the internationally leading manufacturer in the segment of longitudinally welded steel pipes for the petroleum and gas industry. Aside from conventional carbon steel, the company also processes stainless steels and clad steels. The family-run business is headquartered at its parent plant in Erndtebrück in North Rhine-Westphalia, Germany. It employs more than 2000 staff members at 9 different sites worldwide.

To improve the manufacturing process further, EEW contracted the services of INSPECTOR SYSTEMS to design a specialist laser inspection robot to be used as calibration robot at a pipe calibration press. The robot’s task had been clearly defined beforehand: The measurement of the inner surface of longitudinally welded steel pipes during the actual manufacturing process.

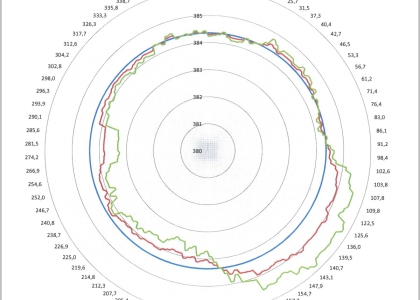

Display indicates where deviations in diameter are outside the tolerances

In the process, the inner diameter and the ovality inside the pipe are continuously measured with an accuracy of +/- 0.1 mm. This ensures that the operator at the machine will immediately receive a notification on the display indicating the sections on the pipe circumference where deviations in diameter are outside the tolerances. This enables him to initiate correcting re-calibration on the extremely heavy pipe calibration press while production is running to keep the pipe shape within the specified tolerances.

360° rotation and approx. 700 positions

The pipes to measure are arranged horizontally and vary between 11.000 mm and 13.000 mm, mm in length, with diameters ranging between 500,0mm and 800,0 mm.

The laser calibration robots can travel forward and backward in horizontal direction. The operator moves the calibration robot to a defined position and then starts the laser measurement. During the measurement, a laser rotates around 360° inside the pipe measuring the respective diameter of the pipe at approx. 700 positions. The maximum ovality is also measured.

Once this measurement is complete, the system compares whether the maximum ovality is within or deviates from the defined pipe tolerances. If the measurement suggests a non-conformity, the operator will turn the pipe into the position of maximum ovality and will calibrate it using the pipe calibration press (mechanical deformation of the pipe). During this process the calibration robot remains clamped at its position within the pipe.