INSPECTOR SYSTEMS Supplies 4 Technologically Unique Video/Laser Inspection Robots for Hungarian Paks Nuclear Power Plant.

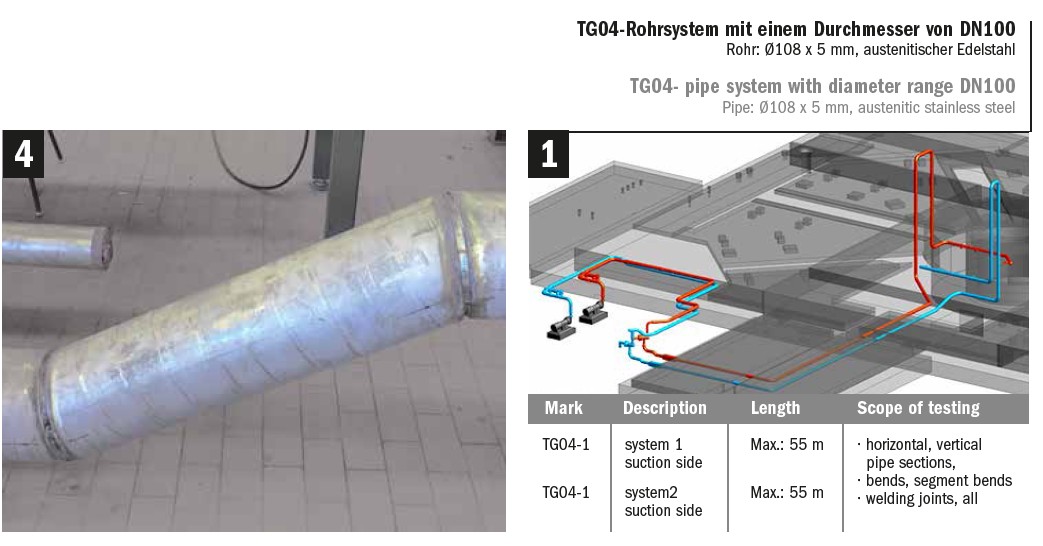

The operating company of Paks Nuclear Power Plant in Hungary announced in 2017 a worldwide public procurement process to develop and fabricate visual and laser inspection robots for the interior inspection of the TG piping systems of revision pools in nuclear blocks 1 – 4.

The pipe sections to inspect are covered in concrete in full length and are therefore not accessible from the outside. Access to the pipe is only possible from one direction through inlets.

The different pipe systems with diameters of 100, 150, 200 and 300 mm are max. 55 m long and consist of up to 7 x 90° (1.5 D) bends with two different vertical sections.

Furthermore, the very challenging pipe systems also include several segment bends of up to 45° and inner diameter variations of up to 50 mm [1].

Developed robots are able to negotiate through challenging pipes with 45° segment bends:

The unique task of this project was to develop visual and laser inspection robots for inspecting the piping system´s interior conditions while driving through segment bends, diameter reducing sections and vertical up and down.

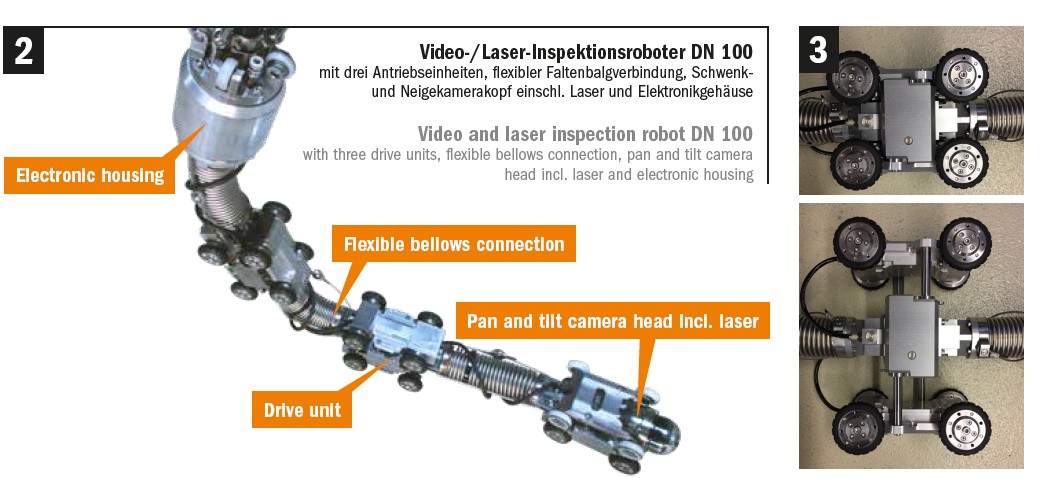

Therefore Inspector Systems developed an innovative robot especially for these specific requirements based on the existing robot technology.

This video and laser inspection robot consists of several drive units with its special rubber coated friction rollers as well as an inspection head, which are flexible connected to each other via folding bellows. This ensures a high degree of bendability and allows insertion into the pipe system even when small amount of space is available.

By means of an adjustable initial tension the friction rollers gets pneumatically pressed against the inner pipe wall and stabilizing and centralizing the robot inside the pipe. As a result, the robot can pass in bi-directional travelling numerous bends with small arc radius ≥ 1.5D, vertical sections ±90°, small diameters and branches.

A special cable connection to the control system outside the pipe system provides the energy supply, data transmission and robot control and further ensures an additional safety pull back functionality [2].

One of the special innovation features of the robot design was the extralong pneumatically stroke of the drive units as shown in the pictures below in order to overcome the required diameter variations and to drive vertically up and down [3]. Another innovation was design of the whole robot to overcome 45° segment bends in forward and backward direction through “sharp” edges inside the bend [4].

Furthermore the need of a special cable design with very low friction that can pull the robot back outside the pipe, even through 7 bends and vertically up in case of a fatal robot failure was a challenging task to achieve.

Conclusion:

Inspector Systems was able to fulfil all specific requirements of driving and inspecting the complicated pipe system mentioned above.

All robots were already delivered through the company Corweld Plus Kft., our partner in Hungary, to the operating company of Paks nuclear power plant and verified in a 1:1 mock up.

Inspector Systems is the only company worldwide who was able to offer a solution for this specific inspection task. No other company could provide a robot solution in this worldwide bidding process.