Inspector Systems develops several radiographic inspection and grinding robots for Framatome SAS - During the operation of a nuclear power plant, preserving the technical-economic efficiency combined with safety are paramount. Ensuring this requires a responsible operational management.

Preventive measures for controlling normal wear and tear and ageing of the plant components determine the technical operating period of a nuclear power plant, which is typically designed for a life span of 40 years. These measures include supervisions, tests and maintenance to be executed on the plant components permanently or periodically.

As part of an action strategy for achieving the operating life and a high standard of quality assurance, one of the largest power producers in the world and the operator of French nuclear power plants initiated a competitive tender process in 2017. With the exception of the steam generator, the contract to be awarded comprised the exchange of several U-shaped components subject to particularly high stress, such as pipe elbows as well as pipelines and branches of the primary circuit of selected 900 MW pressurised water reactors in the coming years. The service to be provided includes preliminary studies, feasibility studies, development of tools, qualifications and execution of replacement work, site logistics, decontamination, etc.

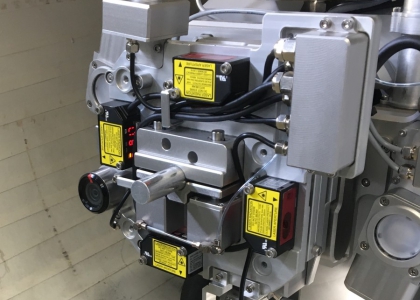

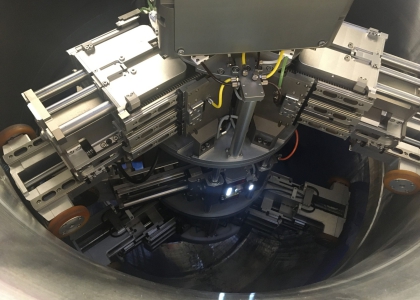

Framatome SAS based in Chalon-sur-Saône / France was awarded the general contract for executing the work. INSPECTOR SYSTEMS, as subcontractor of Framatome part of the bidding process, was awarded the contract for the design and delivery of specialised pipe robot systems for reworking welds followed by radiographic inspection. Two grinding robots and two radiographic inspection robots were required to travel through various pipe diameters ranging from 400 - 800 mm.

As a special requirement, the robots must be able to access the welds to be reworked following the replacement of components. For grinding welds and executing radiographic inspections, it is highly important for the robot to remain securely clamped in the pipe. For the pipe connection of the water supply from the reactor pressure vessel to the steam generator, a robot type must be inserted through the 450 mm manhole of the steam generator, must travel within an inner diameter range of approx. 730 - 790 mm and then, in clamped state, rework or inspect the corresponding welds. Not an easy task since it is well known that physics has its limits.

For this reason, a specialised telescope technology was designed that allows the insertion of the robot through a small diameter range after which it travels through the subsequent larger diameter range to complete the work where it is required. INSPECTOR SYSTEMS is familiar and suited for solutions of this kind thanks to numerous special projects that the company completed in the past and many years of experience in the nuclear power industry.