Upstream – Midstream – Downstream: INSPECTOR SYSTEMS was assigned with the task of visually inspecting several pipe sections for corrosion deposits on the inner pipe surfaces in a process plant on an offshore platform in the North Sea, approx. 300 kilometres off the Norwegian coast. These were up to 60 m long 20 to 24 inch pipes, partly with vertical sections and bends.

Oil and gas drilling is carried out at depths between 70 and 80 metres in this area. The entire field, consisting of a complex of several platforms interconnected by bridges, is the centre and hub of an expansive extraction area.

On the platform in question, oil and gas is processed before being pressurized and transported to land through export pipes of several hundred kilometres length.

The inspected pipes form part of a comprehensive compressor station. These types of process plants are required for many applications in the upstream and midstream sector of the oil and gas business, such as, for instance, gas transport. While the natural gas flows through a pipeline, the differences in distance, friction and height decelerate the movement of the gas and reduce the pressure. Compressor stations are needed to maintain the pressure and flow of the gas. Most oil wells produce a mixture of oil, gas and water, which is then separated above ground. This process also uses compressor stations e.g. as part of an oil processing plant, to separate the gas from the oil in multiple decompression steps.

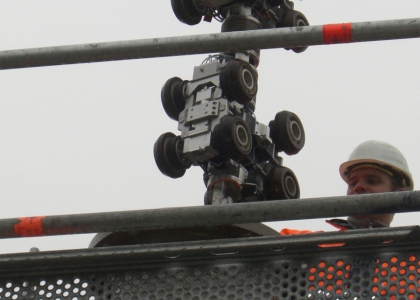

A video laser inspection pipe robot of the type 6.000 (for inner diameters ranging from 440 - 800 mm) with a high-resolution colour camera system and point laser was used for measuring defects. The tried-and-tested design of the INSPECTOR SYSTEMS pipe robot technology also permitted travelling through vertical sections and bends.

Aside from meeting the general technical and logistical requirements of this project, the special qualifications in terms of equipment and personnel as applicable for the offshore industry also had be fulfilled. All requirements were fully met since INSPECTOR SYSTEMS has operated in this environment for many years.

What does upstream, midstream and downstream mean?

When listening to or reading any news about the oil and natural gas business, odds are that these three terms will come up. But what do they actually mean?

-

Upstream

This refers to everything relating to the search for and exploitation of oil and natural gas. Geological surveys and any procurement of information that is used for locating specific areas where oil and natural gas deposits are likely to be found, are generally referred to as “exploration”. The term "upstream" also comprises the steps of the actual drilling on the seabed and the transport of oil and natural gas to the surface, the so-called "production".

-

Midstream

The "midstream" segment of the oil and gas industry refers to everything that is required for transporting and storing the crude oil and natural gas prior to refining and processing. Midstream comprises pipelines and the entire infrastructure that are required for transporting these resources over long distances, including pump stations, oil tankers, tank wagons, etc.

-

Downstream

The last sector of the oil and gas industry is called "downstream". This includes everything needed to convert crude oil and natural gas into thousands of different products. Some of the most obvious products are fuels, such as petrol, diesel, kerosene, domestic fuel oils, etc. Long-chain hydrocarbons, which are present in both oil and natural gas, on the other hand, are used in the production of countless products, such as synthetic rubbers, fertilizers, preservatives, plastics, clothes, paints, etc.