Four new remote field eddy current (RFEC) inspection robots delivered. RFEC inspection technology for inspecting district heating pipes increasingly in demand.

After Inspector Systems developed a pipe robot for the first time with remote field eddy current inspection technology and tested it extensively during the trial phase at the largest urban district heating network operator in France, the French energy supplier and district heating network operator CPCU (Compagnie Parisienne de Chauffage Urbain) in Paris (INSIGHT 2018), there was nothing standing in the way of the permanent use of this inspection technology in combination with our advanced pipe robot systems.

Remote field eddy current inspection technology is a fast and reliable inspection method for defect depth determination and detection of uniform pipe wall thinning (wall thickness reductions). In contrast to conventional eddy current testing, material changes can be measured within a larger area. This inspection method has the advantage of allowing almost equal detection sensitivities on both the outer and inner surfaces of ferromagnetic tubes.

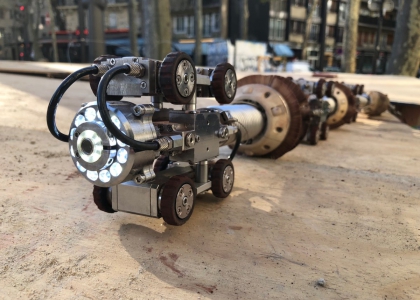

Metropole 1: Diameter DN 80 to 175 to Paris

The experiences at CPCU with the remote field eddy current testing technology, which, incidentally, is supplied by the company Zetec - the specialist for eddy current measuring techniques - have existed for years. However, up to now only inspection pigs, which require openings in the road for insertion and removal and are also limited in distance to only a few dozen meters, were able to be used for this purpose. A very big challenge organizationally and in terms of effort in the busy streets of Paris.

In order to minimize the impact of the associated traffic disruptions and disruptions to the daily lives of residents for such necessary inspections for the maintenance of the district heating network, self-propelled pipe robots with remote field eddy current inspection technology from Inspector Systems will be deployed in the future. After a successful test phase and due to the high robot performance observed during this phase, CPCU immediately decided to purchase three inspection robots covering the diameter ranges DN 80, DN 100 to 125 and DN 150 to 175. With only one access point needed to insert the robot into the pipe system and the ability to travel up to 150 meters in one direction through bends and inclines, this means a considerable simplification in the planning and carrying out of future inspections.

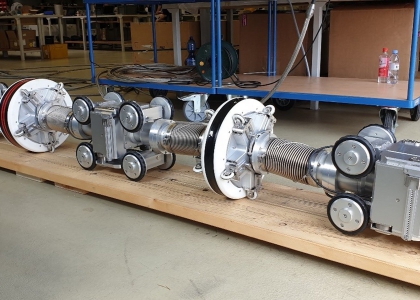

Metropole 2: Diameter DN 400 to 600 to Moscow

The Russian company SU-87 which, from its Moscow location, has been implementing the most complex projects in the field of planning, laying, maintenance and repair of pipelines for many years, was also impressed by the pipe robot technology from Inspector Systems. The focus here is on extensive water, sewer and district heating networks. Being always receptive to innovative inspection technologies, SU-87 decided to purchase the new pipe robot system with remote field eddy current inspection technology from Inspector Systems.

In the future, it will be used mainly in the world's largest and oldest heating structure, the Moscow district heating network. Three quarters of all households there are connected to district heating lines – accordingly, a lot of work for the inspection robot. The pipe robot system itself has a modular design and consists of three drive units which can be flexibly combined with a remote field eddy current module of size DN 400, DN 500 or DN 600 as required. Connected to a cable drum, non-piggable distances with bends and gradients of up to 300 meters can be inspected - a system, which of its kind, is probably unique.