INSPECTOR SYSTEMS carries out demanding internal weld seam processing in Greece and the USA

Over the past year, INSPECTOR SYSTEMS has completed two technically extremely demanding maintenance projects on two continents: one at the Greek alumina plant of METLEN Energy & Metals (Agios Nikolaos) on behalf of Mytilineos S.A., and the other at the large Simplot Phosphates LLC site in Utah (USA) as part of a Paradigm/Simplot project. In both cases, the focus was on the mechanical repair of circumferential welds (girth welds) in large-scale piping systems with the aim of sustainably optimizing structural integrity, media flow and operational safety.

Technical scope of the project: Different plants, same precision

In Greece, the project involved a monotube heat exchanger with eight parallel stainless-steel pipes per section, each approx. 50 meters long and with an internal diameter of 255 mm. A total of up to 64 orbital welds had to be machined inside the pipes. The complex geometry and limited accessibility placed the highest demands on robot guidance and positioning accuracy.

In the US state of Utah, the challenge was to process a section of the approx. 155 km long pipe network within Simplot Phosphates LLC – one of the largest phosphate production sites in North America. Only certain accessible sections of the 10-inch pipe system (internal diameter: 242.25 mm) could be processed. Here too, the focus was on the targeted removal of weld spatter and unevenness to ensure flow-optimized inner surfaces.

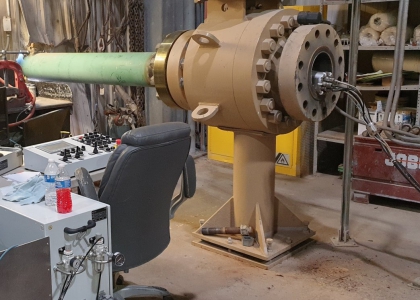

GR 4.000 robot technology – proven worldwide

Both projects were implemented using the modular GR 4.000 grinding robot – a solution developed in-house for medium pipe diameters of 8–12 inches. The robot has a precise feed system and a low-vibration grinding head that enables segment-precise machining along the seam zones. Especially the system's self-propelled feed mechanism proved particularly useful for long pipe sections without external access. In both cases, the grinding work focused on the controlled reduction of weld seam elevations, edge transitions and geometric irregularities without falling below the permissible wall thickness. At the same time, great importance was attached to effective dust extraction in the US project in order to leave the inner surfaces permanently clean and ready for use.

Results: Technical success under extreme conditions

Whether in the summer heat of Southeast Europe or the sparsely populated wilderness of North America, the combination of robust grinding robotics and experienced service personnel enabled both projects to deliver on-time, specification-compliant results. The processed pipe systems subsequently met all material and geometric specifications and could be put back into operation immediately.