Inspector Systems develops and supplies numerous customized robots for Framatome

To ensure the safe and continuous operation of a nuclear power plant, normal wear and tear and ageing of plant components require a continuous quality assurance process. This includes preventive measures such as monitoring, inspections, maintenance, etc., which must be carried out on the plant components either permanently or periodically. This results in maintenance measures such as repairs or replacements and may affect individual components in a nuclear power plant or lead to a comprehensive strategy for multiple nuclear power plants of the same design. Depending on the complexity of the repair or replacement of components, the services to be provided include preliminary investigations. Such as feasibility analysis, development of special tools, qualifications and execution of repair/replacement work, etc.

Decades of experience with special projects in the nuclear industry

Framatome was awarded the contract to carry out targeted overhaul on the primary circuits of pressurized water reactors. The projects are scheduled to be completed within different time frames and are planned to run over several years. The primary goal is to prevent unexpected corrosion processes by replacing particularly stressed components such as elbows, valves and certain welded joints, which also requires the replacement of entire pipe sections to ensure system integrity.

INSPECTOR SYSTEMS was involved in the project at an early stage by Framatome and commissioned as a subcontractor to develop, build and deliver an entire fleet of customized pipe robots for a wide range of applications. It is also important to note the decades of cooperation between Framatome and INSPECTOR SYSTEMS and the enormous amount of knowledge they have accumulated about the use of pipe robots in complex piping structures for inspections, non-destructive testing and mechanical processing methods. Furthermore, it was possible to draw on the development experience gained from a similar pressurized water reactor project, which was completed shortly before.

Robot fleet for pipe sizes ranging from 10 to 27 inches

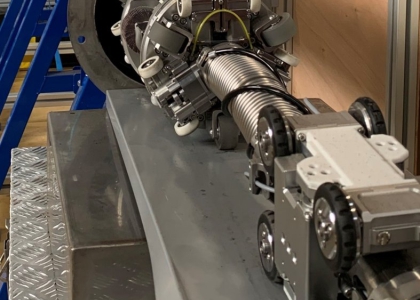

The majority of the robot fleet includes grinding technology originally invented by INSPECTOR SYSTEMS for the targeted machining of internal weld seams, followed by an extraction system designed to removing the grinding dust. In addition, a gripper arm system provided by Framatome and adapted to the pipe-robot supports the removal of other foreign particles in the pipeline. Non-destructive tests such as visual inspection, axial laser scanning and gamma ray inspection are carried out with the robots to verify the welded joints. In addition, a wide variety of specific modules from Framatome can be adapted and used on a robot system via a special interface. Depending on the application, the robots must also be able to be inserted into the pipeline through confined fittings. These highly complex processes require extensive specifications and must be regularly adapted to the prevailing conditions.

For the 10-inch range alone, several grinding robots and combination robots with extraction and axial laser scanning functions are used. The 27-inch area comprises combination robots, each with triple functions, namely grinding, extraction and axial laser scanning. The 27-inch area also includes gamma robots for radiation testing and additional pipe robots, each equipped with a gripper arm system. These are accompanied by several control systems that are interchangeable, meaning that each control system can be combined with any robot and its application function.

Proven robot platform for the most challenging pipe isometrics

The guaranteed and safe movement of robots inside of pipes, especially in complex pipe structures consisting of several bends and alternating sections from horizontal to vertical and vice versa, requires high-quality design and extensive experience. It is essential that a robot does not get stuck or fall from a vertical section. In addition, a robot must be able to stabilize itself securely at any desired point in a pipe for as long as a test or processing operation takes. The core technology of all pipe robots from INSPECTOR SYSTEMS is the unique and thousands of times proven drive system, consisting of one or more drive units. Each drive unit contains two pneumatically extendable wheel carriers, each with four wheels, which securely center and stabilize the robot in the pipe thanks to an adjustable preload. This is a fundamental requirement for performing precise machining or inspections on internal weld seams. The specific geometry and rubber compound of the wheels, in conjunction with the all-wheel drive function, ensures even distribution of the drive forces and provides powerful propulsion. This makes it possible to reach hard-to-access areas in the pipe that are located behind bends, vertical pipe sections, diameter reductions or branches.