Visual inspection robot in use at nuclear power plants

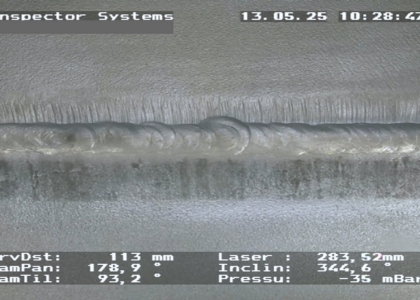

Cooling systems play a crucial role in the safety of energy generation in a nuclear power plant, which is why they are checked regularly. This was also the case with the emergency cooling system at a European power plant, where a pipe robot from INSPECTOR SYSTEMS was used to carry out a visual inspection to detect and measure defects. The total length of the 10-inch pipeline to be inspected, divided into test routes, was over 160 m and included numerous 45° / 90° bends and vertical sections.

After the test specifications had been drawn up with a description of the basic procedure and approved by the power plant operator and an independent expert, work could begin.

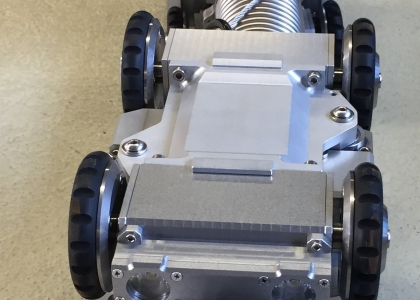

A Video-Laser Inspection Robot type 4.000 (ID 180 to 325 mm) from INSPECTOR SYSTEMS was used, equipped with a high-resolution color camera, 10x optical zoom and automatic/manual focusing. An integrated pan/tilt function allows the camera to rotate 360° and tilt 110°, so that every part of the pipe surface can be inspected.

The lighting direction to the test object and to the optical axis can be selected to achieve optimum image contrast. By varying the illuminance and the variable views from different angles, distracting reflections and shadows can be avoided, thus enabling optimum viewing of any anomalies.

The presence of a point laser also enables the measurement of heights, depths and widths. Due to the robot's ability to cover long distances with vertical sections and curves, only very few access points were required for the challenging pipeline. The evaluation of the detailed results was carried out simultaneously with the visual inspection and after completion by reviewing the recorded data, so that a clear assessment of the situation could then be made.